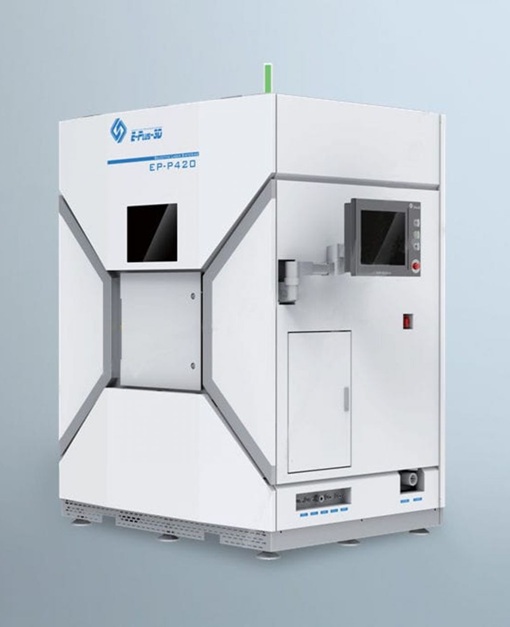

EP-P420 SLS 3D Printer Features

High Performance

- The elimination of left and right excess material box design, resulting in higher powder utilization.

- Optimized temperature real-time management system, temperature filed fluctuation ≤ ±1.0°C.

- Advanced optical scanning path strategy, ensures superior details and surface quality of final parts.

- Incorporating a chip-type heating solution for operation temperatures up to 230°C , enhancing the machine's ability to print a variety of polymers with faster, uniform heating.

- Discrete variation of mechanical properties for full-scale printing parts is less than 5%.

- The temperature field utilizes dual-probe detection with self-calibration function, for more stable and secure printing

User-Friendly & Intelligent

- One-click scanning path generation

- Capability to print with one-click

- Printing report automatic generation, the printing process can be tracked

- Malfunction automatically process, avoids damage to the equipment

Technical Specifications

|

Build Volume |

420 x 420 x 465 mm (L x W x H) |

|

Dimension |

2378 x 1394 x 2505 mm (X x Y x Z) |

|

Gas Supply |

N2 |

|

Machine Weight |

3000 kg |

|

Scanning Speed |

Max. 15 m/s |

|

Max. Chamber Temperature |

230 °C |

|

Power Supply |

AC 380 V, 50 / 60 Hz, 15 kW |

|

Layer Thickness |

0.06 - 0.2 mm |

|

Laser Power |

CO2 Laser, 120 W |

|

Building Speed |

2500 cm3/h |

|

Thermal Field Control |

Independent four-zone temperature control system |

|

Temperature Regulation |

Continuous real-time building surface temperature monitoring |

|

Control Software |

EPControl, EPHatch |

|

Output Data Format |

STL .OBJ .STEP or other convertible file |

|

Material |

PA11, PA12, PA6 and it's composites |